The feed furnace for propane dehydrogenation reaction with the largest single production capacity in the world as a general contractor of Jiangsu Yanxin was successfully put into operation

Source:Jiangsu Yanxin Science & Technology Inc. Release time:2023-02-02 14:37:34 Author:2023

Qingdao Jinneng new materials and hydrogen energy comprehensive utilization project adopts catofin process of Lummus and Basell process technology to build 900KT/a PDH and 8×60KT/a carbon black recycling project,2×450KT/a high-performance polypropylene project, 900KT/a propane dehydrogenation co production of 260kT/a acrylonitrile and 100KT/a MMA project and raw material storage project. The project adopts the unique domestic circular production mode. It is the largest PDH in the world.

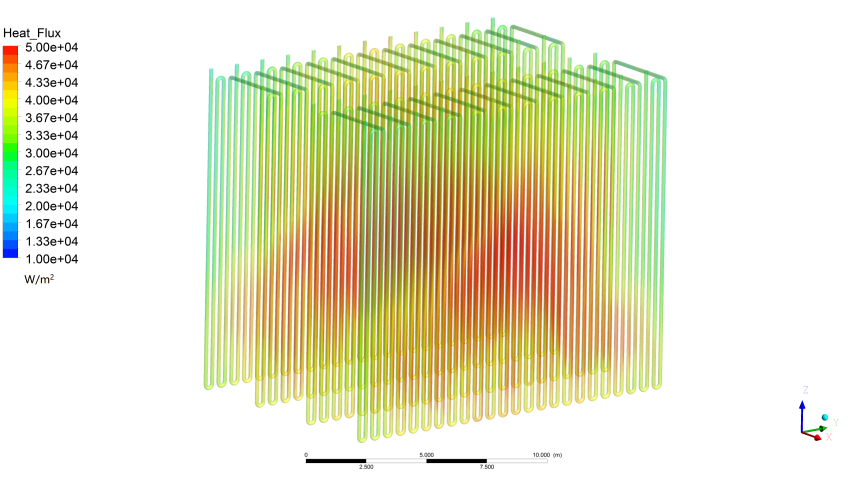

The core equipment of the 900KT/a PDH -reactor charge heater is EPC contracted by Jiangsu Yanxin Science & Technology Incorporated Corporation. It is the largest reactor charge heater of dehydrogenation project in the world. The purpose of the Reactor Charge Heater is to heat the CATOFIN reactor feed to the desired temperature .It is designed to heat the reactor feed from 450℃(minimum 420℃) to an outlet temperature of 590℃ at Start-of-Run(SOR) conditions of the CATOFIN reactors and 600℃ at End-of-Run(EOR) conditions ,with a maximum of 625℃。The design feed rate is 330000kg/h, the total heater absorbed duty is 72MW, the Fuel efficiency calculated (LHV) is 94%, and the flue gas temperature leaving stack ≤110℃.

As the world's largest PDH Reactor Charge Heater, there is no precedent for reference from design, manufacturing and on-site installation. With rich experience in PDH, Jiangsu Yanxin has optimized the design and calculated the whole and even the each component of the Reactor Charge Heater, including structure, strength, pipeline stress analysis, fatigue analysis, heat insulation, combustion and heat transfer CFD simulation, etc.

We pay more attention to ergonomics in design, fully consider the owner's operation and maintenance space requirements. We set up flue gas ducts and air ducts reasonably, and have reserved enough operating space for bottom burner and top manifold.

Figure 3 Operating space at the bottom burner

Figure 4 Operating space at inlet manifold

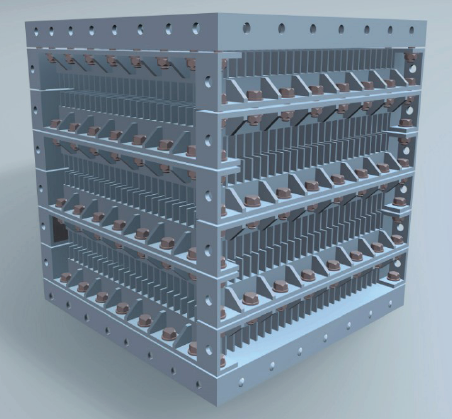

When executing this project, we focus on controlling all links of production quality and on-site installation. All site welds RT tests had reached grade I in NB/T47013.2-2015 《Nondestructive testing of pressure equipments》Part 2:Radiographic testing.

Figure 5 Convection to Radiation Transfer Line

Figure 6 Convection section material inlet 24 pipe side branch pipe

The Paris Agreement on climate change charts the course for the world to transition to low-carbon development. China also calls for energy conservation and emission reduction, So we have the responsibility to implement the national "emission peak and carbon neutrality" policies and develop new heater fittings, including new low nitrogen and high efficiency burners, combined air preheater, new manhole doors and fire doors, new sealed regulating baffles, etc. These new products are widely used in Qingdao Jinneng Reactor Charge Heater, which optimize the air leakage and heat loss of the heater. The maximum thermal insulation performance is achieved through the combination of refractory materials. The radiant floor and wall temperature is 35 ~ 50 ℃ (no wind, ambient temperature is 18℃). The heat loss of the heater is less than 1.5%, reducing the user's fuel cost, achieve saving energy and reducing emissions.

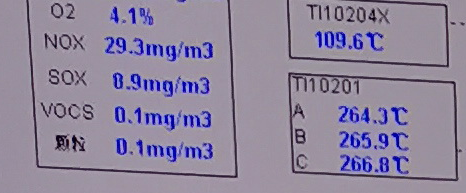

Figure 7 New energy-saving integrated manhole door with fire door

Figure 8 Combined air preheater cast iron heat exchange module

Burners are almost foreign brands in previous projects. Qingdao Jinneng applied the "Yanxin " new ultra-low nitrogen and high efficiency burner for the first time on Reactor Charge Heater and work well. The real-time NOx emission is 29.3mg/m3 at 100% load, 780 ℃ in radiant section and 4.1% oxygen which fully meets the project requirement that the NOx emission shall not be greater than 50mg / m3.

Figure 9 Working condition diagram of the burners on both sides

Figure 10 Working condition of intermediate burner

Figure 11 On-site measured emission data

Lummus has informed us that the Jinneng CATOFIN PDH unit is now producing on-spec propylene product. This is a great news, and Lummus and Jinneng should be proud of this significant achievement.