Soot Blower

- Direct supply from the manufacturer

- Order phone:+86-189 2123 2972

- E-mail:zhangjiahao@chinayanxin.com

Detail

Advocate low carbon, energy saving and emission reduction

Our company has always adhered to the basic national policy of the country's low-carbon economy. Under the background that the state advocates energy conservation and emission reduction for high-energy-consuming enterprises, our company is entrusted by Sinopec Corporation to develop a new generation of steam soot blowing system. Heating furnace is a large energy consumer in the petrochemical industry. The energy consumption of heating furnace accounts for more than 50% of the total energy consumption of oil refining enterprises. As a leading enterprise in the design and manufacture of heating furnaces, Yanxin should play a leading role.

A large amount of flue gas will inevitably appear in the production of the heating furnace. When the flue gas passes through the convection section, the air preheater and the boiler economizer tube bundle, the surface ash of the furnace tube will reduce the thermal conductivity, and the exhaust gas temperature will increase, resulting in heat loss. , The function of the soot blower is to remove ash on the surface of the furnace tube, remove the slag and improve the thermal conductivity, but the old-fashioned soot blower is prone to mechanical failures such as the soot blowing gun jamming, so the economic efficiency is not high. At that time, there were basically no technological breakthroughs in China, but the tireless Yanxin people were not afraid to endure hardships and worked hard to solve problems. Finally, with the efforts of all employees of the group company, a new generation of intelligent steam soot blowing system was born. The new generation of sootblowers not only makes up for the deficiencies of the old model sootblowers but also adds the following features:

After the intelligent soot blowing system is adopted, the exhaust gas temperature of the chimney after adding the steam soot blower to the original heating furnace is reduced by 10%-20%. After one year of operation with steam sootblower added to the newly built reheating furnace, the chimney exhaust temperature of the reheating furnace is no more than 10% higher than that at the beginning of operation

2. Adopt PLC control cabinet, a set of intelligent control valve, intelligent temperature measuring hydraulic gauge, soot blower, steam pipeline, etc. to form an optimized soot blowing system to realize automatic condensation removal and intelligent soot blowing.

3. When the soot blowing medium is saturated steam, set steam-water separator and condensate discharge control valve to separate steam and water and discharge condensate. When the soot blowing medium is superheated steam, a condensate discharge control valve is set to discharge the condensate to prevent the condensate from being brought into the furnace.

4. According to the characteristics of high temperature in the convection section of the heating furnace and the boiler, a new type of soot blower is re-developed, and the parts are processed by numerical control equipment to improve the processing accuracy and eliminate the mechanical failure of the previous soot blower.

5. Eliminate the problem of steam leakage from the soot blower, and reduce the phenomenon of running, running, dripping and leaking.

6. The valve body of the soot blower has pressure adjustment to meet the purging requirements during soot blowing.

Classification of intelligent sootblowers

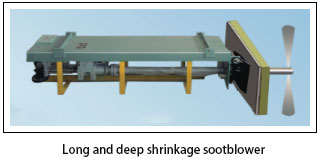

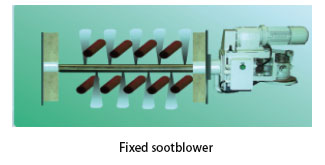

For different working conditions, we are equipped with different forms of steam sootblowers to prevent mechanical failures. There are fixed rotary and long telescopic rotary sootblowers. The fixed rotary soot blower is mainly used for installation in the section where the furnace stability does not exceed 550 degrees. According to the needs, it can effectively purify the ash deposits at a certain purging angle. When the furnace temperature exceeds 550 degrees, a long telescopic rotary sootblower is generally used to purge the furnace tubes with superheated steam medium.

Our company has always adhered to the basic national policy of the country's low-carbon economy. Under the background that the state advocates energy conservation and emission reduction for high-energy-consuming enterprises, our company is entrusted by Sinopec Corporation to develop a new generation of steam soot blowing system. Heating furnace is a large energy consumer in the petrochemical industry. The energy consumption of heating furnace accounts for more than 50% of the total energy consumption of oil refining enterprises. As a leading enterprise in the design and manufacture of heating furnaces, Yanxin should play a leading role.

A large amount of flue gas will inevitably appear in the production of the heating furnace. When the flue gas passes through the convection section, the air preheater and the boiler economizer tube bundle, the surface ash of the furnace tube will reduce the thermal conductivity, and the exhaust gas temperature will increase, resulting in heat loss. , The function of the soot blower is to remove ash on the surface of the furnace tube, remove the slag and improve the thermal conductivity, but the old-fashioned soot blower is prone to mechanical failures such as the soot blowing gun jamming, so the economic efficiency is not high. At that time, there were basically no technological breakthroughs in China, but the tireless Yanxin people were not afraid to endure hardships and worked hard to solve problems. Finally, with the efforts of all employees of the group company, a new generation of intelligent steam soot blowing system was born. The new generation of sootblowers not only makes up for the deficiencies of the old model sootblowers but also adds the following features:

After the intelligent soot blowing system is adopted, the exhaust gas temperature of the chimney after adding the steam soot blower to the original heating furnace is reduced by 10%-20%. After one year of operation with steam sootblower added to the newly built reheating furnace, the chimney exhaust temperature of the reheating furnace is no more than 10% higher than that at the beginning of operation

2. Adopt PLC control cabinet, a set of intelligent control valve, intelligent temperature measuring hydraulic gauge, soot blower, steam pipeline, etc. to form an optimized soot blowing system to realize automatic condensation removal and intelligent soot blowing.

3. When the soot blowing medium is saturated steam, set steam-water separator and condensate discharge control valve to separate steam and water and discharge condensate. When the soot blowing medium is superheated steam, a condensate discharge control valve is set to discharge the condensate to prevent the condensate from being brought into the furnace.

4. According to the characteristics of high temperature in the convection section of the heating furnace and the boiler, a new type of soot blower is re-developed, and the parts are processed by numerical control equipment to improve the processing accuracy and eliminate the mechanical failure of the previous soot blower.

5. Eliminate the problem of steam leakage from the soot blower, and reduce the phenomenon of running, running, dripping and leaking.

6. The valve body of the soot blower has pressure adjustment to meet the purging requirements during soot blowing.

Classification of intelligent sootblowers

For different working conditions, we are equipped with different forms of steam sootblowers to prevent mechanical failures. There are fixed rotary and long telescopic rotary sootblowers. The fixed rotary soot blower is mainly used for installation in the section where the furnace stability does not exceed 550 degrees. According to the needs, it can effectively purify the ash deposits at a certain purging angle. When the furnace temperature exceeds 550 degrees, a long telescopic rotary sootblower is generally used to purge the furnace tubes with superheated steam medium.

The picture below shows the experimental site of the sootblower

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible